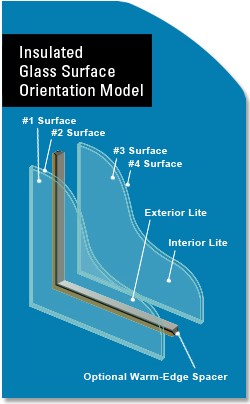

Insulated Glass

Based on today's energy efficient mandates and specification, UGC fabricates high-quality, dual-sealed insulated units to meet the needs of the architectural and glazing community. UGC's insulated units are available in a variety of thicknesses, as well as a number of contemporary tints, reflective coatings, and low-emissivity glass, containing decorative muntins/grids, as well as argon gas to reduce the units overall U-value. All UGC insulated units are certified by the Insulating Glass Certification Council (IGCC) and conform to ASTM E2188, ASTM E2189, and ASTM E2190.

World Class...

State-of-the-art Lisec automation and robotic equipment producing clean, accurate, high-quality, warranted insulating units meeting or exceeding customer expectations.

Warm-Edge Spacers

Warm-Edge Thermal Spacer Technology

Warm-Light® Thermally broken aluminum spacer technology by AZON

UGC and AZON have teamed up to deliver one of the industry's most technologically advanced warm edge spacer system.

Q - Why use warm-edge technology in commercial glass applications?

A - To save energy, lower utility costs, experience less condensation and to provide a more comfortable environment. The combination of thermally improved frames and high performance glass have made the air space material the weak link in the overall glazing system. Adding a thermal barrier in the air space material dramatically reduces the transfer of outside climatic conditions resulting in improved overall thermal performance.

Q - How does Warm-Light work so well?

A - Thermal conductivity is the key. The thermal conductivity of conventional spacer (the lower the number the better) is 1,109. Stainless steel spacer material has a thermal conductivity of 99 and this is 11 times better than aluminum in terms of thermal conductivity. Warm-Light has a thermal conductivity of .84 and is more than 100 times better than stainless steel. The polyurethane core creates a true thermal barrier.

UGC is a Certified Fabricator of Warm-Light® by AZON